Schlüter-KERDI-LINE is a multi-piece, linear drainage system for creating floor-level showers with ceramic tiles, natural stone or coatings.

It consists of a formed stainless steel channel body with a grate and frame structure, which can be seamlessly adjusted to the floor covering thickness using the supplied installation aid in the set. The frame structures are available in two versions. You can choose between a profile frame with a 10 mm wide visible surface in a brushed, polished or powder-coated finish or a contour frame.

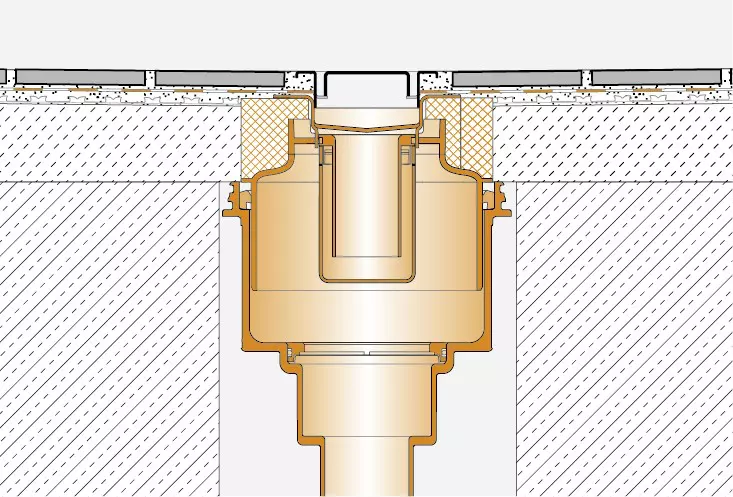

Schlüter-KERDI-LINE-V 50 G2 for vertical drainage features an integrated odour trap. In compliance with DIN EN 1253, it has a drain capacity of ≥ 1.0 l/s with an accumulation height of 2 cm and a water trap height of 50 mm.

Channel support height:

In the case of KERDI-LINE-H 50 and -H 40, the channel body is inserted into precisely fitting polystyrene channel support for quick and easy installation. Due to the drain design, the channel body and channel support of KERDI-LINE-V, -H 50 G2 and KERDI-LINE-F are permanently connected.

KERDI-LINE can be universally used for intermediate installation in floors or at wall areas.

Length of KERDI-LINE-H, -H 50 G2 and -V, -VS, -V 50 G2 linear drainage:

- 50 cm to 180 cm (VOS = off-centre from 70 to 120 cm) in increments of 10 cm

The perimeter of the channel body consists of an adhesive flange with a pre-adhered KERDI collar.

It ensures the reliable connection of the channel body to the bonded waterproofing assembly, both in the floor area and on upright walls.

In conjunction with the waterproofing systems Schlüter-KERDI, Schlüter-DITRA, Schlüter-DITRA-HEAT or Schlüter-KERDI-BOARD and the matching system adhesives Schlüter-KERDI-COLL-L or Schlüter-KERDI-FIX, installers can create certified bonded waterproofing assemblies with connecting linear drainage.

Note: Schlüter-KERDI-LINE and frame assemblies must be installed with cement-based tile adhesives. The use of acetic-crosslinking silicone is not permissible on channels, frames and grates.

KERDI-LINE is a system component that complies with the German waterproofing standard DIN 18534. Together with the above-listed Schlüter-Systems it has general technical approval (abP) in Germany.

Please refer to the respective product data sheets for information about the moisture exposure classes according to abP. KERDI-LINE is a system component with European Technical Assessment (ETA) according to ETAG 022 (watertight covering kits). Schlüter products tested together with KERDI-LINE bear the CE mark.

The visible surfaces of the profile frame and grates - both in the closed and embossed version - are made of brushed, polished stainless steel or powder coated stainless steel. A 17 mm deep tile pan is available for the profile frame. In addition, we offer a frameless covering support that is suitable for any height (KERDI-LINE-D).

Schlüter-KERDI-LINE-GTO is an odour trap with a silicone dry flap. It can be installed instead of a two-piece odour trap and prevents odours in situations when infrequent use of the drain (in guest bathrooms, holiday homes etc.) could result in the water in the odour trap unit from evaporating. With a drain capacity of at least 0.4 l/s (according to DIN EN 1253), the waterless odour seal can also permanently replace the standard odour trap unit, for example to prevent inadequate venting in the drain system (cannot be combined with KERDI-LINE-F / -VS / -VOS).

Note:

Due to the variable drain construction, KERDI-LINE-H 50 G2, -V 50 G2 and KERDI-LINE-F require the installation of a sloped screed. The surface of the screed must be waterproofed with Schlüter-DITRA (see product data sheet 6.1) or DITRA-HEAT.

Schlüter-SHOWERPROFILE-S and -R (see product data sheet 14.1) are supplementary components for creating a floor or wall connection. SHOWERPROFILE-S has a triangular design to conceal the sloped lateral edges of floor level showers. Waterproof the surrounding walls with Schlüter-KERDI (see product data sheet 8.1) or create a bonded waterproofing assembly with Schlüter-KERDI-BOARD (see product data sheet 12.1).